John Deere

9RT 540 Tractor

4WD & Track Tractors

Equipment Description

- Engine HP1: 595 Max/ 540 Rated

- Fully integrated precision ag technology

- e18™ PowerShift Transmission

- Multiple cab and visibility packages

1Engine power PS (hp ISO) at max engine power speed (ECE-R120). John Deere Standard RES10080, SAE Standards J1995

| Engine performance - Rated power | 397 kW 540 hp |

|---|---|

| Engine performance - Rated PTO power (hp SAE) | 249 kW 335 hp |

| Engine specifications - After treatment type | Diesel oxidation catalyst (DOC)/selective catalytic reduction (SCR) |

| Engine specifications - Aspiration | Dual series turbocharger with fixed geometry first stage and wastegated second stage; air-to-air aftercooling and cooled exhaust gas recirculation (EGR) |

| Engine specifications - Cylinders liners | Wet-sleeve |

| Engine specifications - Description | JD14 (B20 diesel compatible) |

| Engine specifications - Displacement | 13.6 L 827 cu in. |

| Engine specifications - Emission level | Final Tier 4 (FT4) |

| Engine specifications - Engine family | MJDXL13.5334 |

| Engine specifications - Engine type | In-line six, four valve |

| Engine specifications - Rated speed | 2100 rpm |

| Key Specs - Base machine weight | 21,512 kg 47,326 lb |

| Key Specs - Engine description | JD14 (B20 diesel compatible) |

| Key Specs - Engine displacement | 13.6 L 827 cu in. |

| Key Specs - Hydraulic pump rated output | Standard: 208 L/min 55 gpm Optional: 416 L/min 110 gpm |

| Key Specs - Maximum engine power | 437 kW 594 hp |

| Key Specs - Rated engine power | 397 kW 540 hp |

| Key Specs - Rated PTO power (hp SAE) | 249 kW 335 hp |

| Key Specs - Rear hitch category (SAE designation) | Category 4N/N: 6804 kg 15,000 lb Category 4N/N: 9072 kg 20,000 lb |

| Key Specs - Transmission type | John Deere e18™ 18-speed PowerShift™ with Efficiency Manager™: 40 km/h 25 mph |

Featured List

- Track width and Tread Spacing: 30 in. or 36 in. tracks

- PTO HP: Rated: 335 hp (249 kW)

- Hydraulics: 55 or 110 gpm

SCV 4-8 factory installed - Transmission: e18™ PowerShift with Efficiency Manager

- Engine HP¹: Max: 595 hp (437 kW)

Rated: 540 hp (397 kW) - Ride Comfort: AirCushion™ Suspension

Featured Content

9RX Tractor

When you’re trying to get a field planted before weather moves in, there’s no time to hit a scheduled maintenance interval or get smacked with an unexpected repair. That’s why we designed the 9 Series for maximum reliability and less in-season maintenance.

To start, we simplified as many systems as possible, using components common to other tractor lines and minimizing potential downtime due to parts availability. Then we eliminated as many potential pain points as possible through changes in the cooling, aftertreatment, and diagnostic systems, including:

- Replacing the fan drive system with a maintenance-free hydraulic fan drive

- Streamlining aftertreatment with a single-canister inline system that’s simpler and features fewer parts

- Improving uptime by adding better descriptions to diagnostic codes and offering predictive diagnostics through John Deere Expert Alerts

- A front-left service panel for easier access to engine oil check and fill points;

- Offering a 500-hour oil change interval on the John Deere JD14 (13.6L/827-cu in.) Final Tier 4 (FT4) engine when using approved John Deere oil and filter.

Maximizing uptime using connectivity and technology

Your needs and success are the focus of John Deere. John Deere makes it easy for you to benefit from having a connected tractor in your operation. All tractors come standard with JDLink™ telematics system and users can turn on connectivity in the John Deere Operations Center™ application. With a StarFire™ Integrated Receiver and G5Plus Display, you can easily step right into advanced technology. If you’re an advanced tech user, you’ll enjoy the benefits of a highly intelligent machine connected to a full suite of solutions on the most open platform in the industry. Advantages of a connected machine include:

- A StarFire Integrated Receiver eliminates all setup, installation, and global positioning system (GPS) calibrations

- AutoTrac™ assisted steering guides the machine with accuracy in a variety of field conditions

- Automation is an option with some applications

- John Deere Connected Support™ is a proactive service approach to improve service efficiency and reduce machine downtime

- JDLink gives you access to information anytime, anywhere, to make data driven decisions with John Deere Operations Center and Documentation

The technology and connectivity in John Deere tractors allow you to optimize productivity, increase uptime, and boost profits with machine information from any device, anywhere.

| Large tractor equipment | Precision Technology | JDLink |

Base equipment:

Optional equipment:

|

Base equipment:

Optional equipment*:

|

Base equipment:

|

*Available with G5 Advanced Tractor License, for more information on G5 Advanced Licenses please visit the Precision Ag Technology Guidance, Automation and Autonomy Sales Manual.

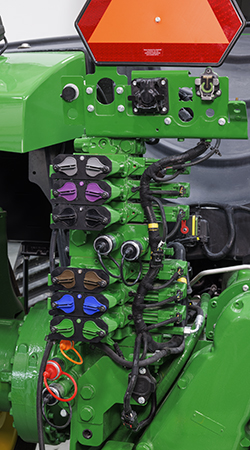

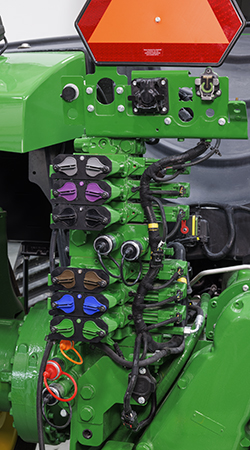

Selective control valves (SCVs) on a 9R Tractor

Of course, the 9 Series has the hydraulic muscle you need to push, pull, lift, and power your most demanding implements. But thanks to a range of enhancements to the hydraulic system, these tractors can provide that power at lower engine speeds, saving you fuel while still giving your implements the capacity they need. Regardless of model or configuration, the new 9 Series hydraulic system gives you:

- An increase of almost 40 percent in charge pump capacity, from 54-cc to 75-cc, to help maintain a higher flow at lower engine speeds

- A new swash plate angle sensor to monitor hydraulic flow and pressure and adjust engine speed to meet demand

- An integrated hydraulic pump, filter, and priority valve for fewer and shorter lines, reduced pressure loss, fewer flow restrictions, and an extra level of reliability

And if you depend on implements that need continuous hydraulic power, the 9 Series Tractors are available with Intelligent Power Management (IPM). Using dual pumps and advanced sensor and control technology, IPM provides additional engine and hydraulic power for high-demand applications like air seeding up and over hills or through thick, tough soil.

Add in single and dual pump options and a flexible number rear SCVs, and you can configure a powerful, fuel-efficient hydraulic system to meet the demands of your specific operation without paying for capacity you don’t need.

SCV stack

9 Series tractors offer a SCV stack aimed at improving performance and aftermarket serviceability. These valves will further enable customers to fine-tune hydraulic flow rates and make it easier and more affordable to customize an SCV stack. Now you can switch coupler sizes without having to change an entire SCV slice.

The 9-series tractor plumbing is designed for max flow so there will be no restrictions in the system making it fast, easy, and cost effective if there is a need to switch between 1.3 cm (0.5 in.) and 1.9 cm (0.75 in.) couplers. Making the change between SCV coupler size will require a new housing and dust protection shield compared to a new SCV slice.

NOTE: Up to six SCVs can be factory installed. 9 Series Tractors can add SCV 7 and SCV 8 as field-installed attachments. See Aftermarket kits for details.

JD14 engine

The JD14 (13.6L/827-cu in.) engine from John Deere Power Systems has the power to handle heavy draft disks and rippers, hydraulically demanding air seeders and planters, and large transport loads like grain carts and slurry wagons. With a durable design and heavy-duty components, you can depend on the Final Tier 4 (FT4)/Stage V compliant JD14 engine, standard in the 291 to 471 engine kW (390 to 640 engine hp) 9 Series Tractors.

We developed the JD14 from the ground up, starting with stronger castings and bearings and tougher internal components, all designed to meet the high demands of field operations. We replaced the fuel injectors with a high-pressure common rail (HPCR) fuel system and eliminated the diesel particulate filter (DPF) to boost fuel efficiency and lower operation and maintenance costs. Integrated coolant and oil passages, along with a new belt-driven water pump, eliminate potential leak points and allow for a less-crowded engine compartment, improving serviceability and reducing debris accumulation.

In redesigning the engine, we also gave it:

- Hydraulic valve lash adjusters to maintain valve-lash settings during engine operation, reduce valve train noise and wear, and allow for greater fuel efficiency.

- A hydraulic fan drive for improved cooling capacity with no required maintenance.

- A new integrated wiring harness design featuring a modular layout for reduced vibration, greater reliability, and easier service and diagnostics.

- A rear gear train that integrates fully into the cast-iron block, reducing engine noise and improving the durability of the crankshaft damper.

- Combination sensors where possible, meaning fewer sensors, connectors, and wires.

- A powerful engine brake that allows operators to use the engine to control tractor and implement speeds while transporting or traveling downhill, reducing wear on the drivetrain brake components.

JD14 engine

The JD14 (13.6L/827-cu in.) engine from John Deere Power Systems has the power to handle heavy draft disks and rippers, hydraulically demanding air seeders and planters, and large transport loads like grain carts and slurry wagons. With a durable design and heavy-duty components, you can depend on the Final Tier 4 (FT4)/Stage V compliant JD14 engine, standard in the 291 to 471 engine kW (390 to 640 engine hp) 9 Series Tractors.

We developed the JD14 from the ground up, starting with stronger castings and bearings and tougher internal components, all designed to meet the high demands of field operations. We replaced the fuel injectors with a high-pressure common rail (HPCR) fuel system and eliminated the diesel particulate filter (DPF) to boost fuel efficiency and lower operation and maintenance costs. Integrated coolant and oil passages, along with a new belt-driven water pump, eliminate potential leak points and allow for a less-crowded engine compartment, improving serviceability and reducing debris accumulation.

In redesigning the engine, we also gave it:

- Hydraulic valve lash adjusters to maintain valve-lash settings during engine operation, reduce valve train noise and wear, and allow for greater fuel efficiency.

- A hydraulic fan drive for improved cooling capacity with no required maintenance.

- A new integrated wiring harness design featuring a modular layout for reduced vibration, greater reliability, and easier service and diagnostics.

- A rear gear train that integrates fully into the cast-iron block, reducing engine noise and improving the durability of the crankshaft damper.

- Combination sensors where possible, meaning fewer sensors, connectors, and wires.

- A powerful engine brake that allows operators to use the engine to control tractor and implement speeds while transporting or traveling downhill, reducing wear on the drivetrain brake components.

Ultimate Visibility package at night

Visibility is more than just lighting. It’s mirrors where you need them, shades for the blinding late-fall and early-spring sun, wipers to help keep all the glass clear, and integrated camera capability. The 9 Series Tractors let you choose the visibility package that best suits your needs – Select, Premium, or Ultimate with 360-degree light-emitting diode (LED) lighting –so you and your operators can run with all-conditions confidence.

| Select | Premium | Ultimate | |

| Lighting | 18 halogen worklights | 18 LED worklights | 24 LED worklights and eight LED convenience lights* |

| Mirrors | Mechanical | Electric and heated | Electric, heated, and telescoping |

| Sunshades | Front | Front, right-hand side, and rear | Front, right-hand side, and rear |

| Wipers | Front and rear | Front, right-hand side, and rear | Front, right-hand side, and rear |

| Cameras | Camera ready | Camera ready | Integrated digital cameras |

| Rear window tint | À la carte option | À la carte option | À la carte option |

*Convenience lights illuminate the corners of the cab for easier entry and exit.

Rear window tint

Rear window tint provides 10 percent light transmissibility (standard glass provides 70 percent light transmissibility)

Offers & Discounts

No matching offers found for "9RT 540 Tractor".